Sales & Operations Planning

Sales & Operations Planning is indispensable in organizations with a large flow of goods. Yet many companies are struggling with it. Understanding what S&OP is all about, why it is important, and what pitfalls your business needs to avoid is crucial in leading successful company!

What is S&OP?

According to Tom Wallace, one of the leading people behind the important initial development of S&OP, “Sales & Operation Planning (S&OP) is a set of decision-making processes to balance demand and supply, to integrate financial planning and operational planning, and to provide a forum for establishing and linking high-level strategic plans with day-to-day operations” (Wallace, nd).

Some decades ago, S&OP started as simple as balancing supply and demand. This so-called “horizontal S&OP” was the beginning of linking Marketing and Sales with the supply chain and manufacturing of the business. However, the real world taught us that these departments have different goals and ambitions. Let’s look at the following dilemma:

- Customer development says that we’ll sell 500 units to our relations

- Marketing says we will sell 300 units after the promotion of the product

- Manufacturing might think that the business can only sell 250 units

These different set of eyes brings a different set of numbers. An advanced S&OP process aims to get one consensus plan for the business.

S&OP melts all business planning (operations, customer service, development, production, etc.) into one oiled machine, ensuring businesses meet various benefits like:

- Sustainable competitive advantages

- Improved forecasting & planning

- Reduced inventory costs

- Higher overall profitability

- Increased Return-On-Investment on any investment

However, it isn’t easy to implement S&OP for many businesses. Many directors and executives struggle with (mainly) the lack of alignment. Further down this article, we’ll:

- discuss the S&OP process more in detail,

- discuss the six common pitfalls in implementing S&OP,

- and last but least, how we at Inchainge can help you educate your managers to become S&OP heroes!

Why is S&OP important?

Involvation researched the significance of implementing S&OP amongst 20 leading multinationals:

- 70% realized improved profitability

- 70% realized on-time delivery

- 70% improved their inventory levels

- 60% reduced their costs

S&OP is essential for many businesses, but why?

- It allows you to have one set of numbers and plans

- It creates cross-functional alignment, breaking down the silos

It bridges the gap between strategy and execution

The Sales & Operation Planning process

Before the S&OP initiative, a company must consider the following four aspects of The Involvation Change Model:

- Why do we want this?

- Are we willing to do this?

- Do we have the processes and technology to do this?

- Do our people know how to do this?

Dr. H. van der Drift explains this model in his webinar “S&OP competency development: the power of simulation.”

You can watch the entire webinar here to learn how simulations and serious gaming can educate your managers in S&OP!

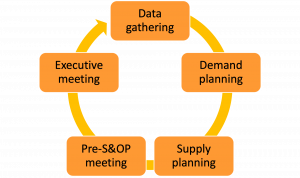

The sales and operations planning process contains the following steps:

- Data gathering

Data is used to make data-driven decisions. Data is gathered about prior sales, and forecasts are made for future sales.

- Demand planning

This is the first time in the process where cross-functional collaboration comes to play. Therefore, it is also considered one of the most frustrating parts of the S&OP process. Scenario analysis is one of the methods used by senior management to understand the impact of supply-chain-side volatility and demand uncertainty.

- Supply planning

With supply planning, the capacity side of the business is evaluated. Planning of manufacturing, operations, and materials come here to play.

- Pre-S&OP meeting

All department heads come together during the pre-S&OP meeting to evaluate the planning and execute where possible. The financial impact of the demand and supply chain planning is being considered during this meeting.

- Executive meeting

Some issues can’t be solved during the pre-S&OP meeting. That is why during this meeting, executives evaluate the recommendations made by the department heads to approve final decisions and the overall S&OP plan.

The diagram below shows the process described above:

The sales and operation planning process diagram.

The highlights of a Sales & Operation Planning process are as follows:

- An S&OP process links the business strategy to execution

- It is a decision process on a tactical and aggregated level

- The horizon of the decisions taken typically extends between 6-24 months. This depends on how quickly a company can adapt its capacity and supply constraints.

- The S&OP process aligns and balances supply and demand. Therefore sales, marketing, operations, purchasing, and supply chain management should be involved.

In a more advanced setting, even finance is involved. It is then called Integrated Business Planning (IBP).

How do you select software for Sales & Operations planning?

Selecting software is never an easy task. When is a software suitable for your business? Hans van der Drift and Martijn Lofvers discussed this question in their article: “The DNA of S&OP software”. According to their research, they suggest that you must select several simple and high-level criteria to build a robust shortlist of potential solutions. Here are some of the thoughts shared in the article, which can be requested here:

- Typical areas of focus

Many solutions are developed with a set of functionalities for a particular industry. Sometimes, these solutions can also be applied to other sectors and markets. However, there is often a mismatch when using these solutions in industries they aren’t designed for.

- References

Every solution has references within a sector in which the solution excels. These references can help you determine the leading software in the industry.

- Size

The size of your business is essential in terms of maintaining a solution. The most advanced and extensive solution might not fit your business best.

- Customer/market complexity

The complexity of the market is essential to determine the flexibility of a solution needed. To what extent do you need collaboration in your business? The answer to that question can help you choose the required complexity of a solution.

The specific criteria are different per business. These questions should help you to get started on building your robust shortlist!

S&OP: simple but not easy

Nowadays, S&OP has made it into the top-level agenda of most leading firms around the planet, even though many companies still struggle to get it right. On the one hand, this might be surprising since the process steps are not that complicated. The complexity is that you try to align several departments that are not used to speaking each other’s language. Dr. Lapide (Research Director at MIT’s Center for Transportation and Logistics) published in “The Journal of Business Forecasting” (fall 2004) 12 success factors of the S&OP process:

- Ongoing routine S&OP meetings

- Structured meeting agendas

- Pre-work to support meeting inputs

- Cross-functional participation

- Participants empowered to make decisions

- An unbiased, responsible organization to run a disciplined process

- Internal collaborative process leading to consensus and accountability

- An unbiased baseline forecast to start the process

- Joint supply and demand planning to ensure balance

- Measurement of the process

- Supported by integrated supply-demand planning technology

- External inputs to the process

Ten common pitfalls in implementing S&OP

While implementing sales and operations planning, you should be aware of the following pitfalls:

- There can be a lack of commitment in some of the needed departments

- The agenda of the pre-S&OP meeting is filled with S&OP-unrelated points

- Department politics doesn’t help to create a clear picture

- Targets and forecasts are mixed

- Discussion about numbers instead of the underlying assumptions

- Discuss only a short horizon instead of a midterm

- Too detailed plans and discussions

- There is only time to talk and listen to Supply Chain instead of focusing on the future and solving problems.

- There is not an S&OP dashboard to make KPIs and goals visual

- Managers tend to come unprepared for pre-S&OP meetings because of their busy schedules. However, the time of this meeting is limited. Dwelling too long on the problems, don’t solve them faster.

The only source of knowledge is experience – Albert Einstein:

As mentioned in the previous paragraph, one of the most common pitfalls of implementing S&OP is the lack of alignment. Forbes said in its article “Five Ways Sales and Operations Planning Enables Success and Drives Business Integration” the following:

A strategic view, which sees the mission as one of driving lasting value for all parties in the supply chain, will be more sustainable and deliver advantages far beyond the basic benefit of cost savings. Many of the challenges the C-suite faces are therefore cultural and stem from a lack of alignment of the various functional pieces into an integrated whole. – Steven Bowen, CEO Maine Pointe

Inchainge offers three different learning solutions powered by our business simulation games:

- With the S&OP learning solution, you’ll learn and experience the S&OP process of a manufacturer. This solution is powered by The Fresh Connection, a business game focused on value chain management.

- You’ll go a step further with the S&OP and Multichannel supply chain management learning solution! This advanced module of The Fresh Connection brings S&OP and the complexity of a multichannel

- Integrated Business Planning is the most advanced learning solution powered by The Cool Connection. This solution takes S&OP to a whole other level! In this learning solution, you’ll learn how to integrate the planning cycle of S&OP with the financial planning cycle.

All our business games are made with the principles of experiential learning. It covers developing hard and soft skills. The picture below demonstrates The Fresh Connection. Get in contact with us, and we’ll provide you with a customized learning experience for you and your team.

Now you know

Now you know

S&OP in the early days meant only bringing supply and demand together. These days S&OP evolved into one consensus plan across departments and from the top-down. This alignment is hard to achieve due to common pitfalls, like a lack of commitment. The process of S&OP exists of five steps: data gathering, demand planning, supply planning, pre-S&OP meeting, and executive meeting. This process can be measured by the 12 success factors of Dr. Lapide. Educating managers in S&OP and IBP can be done with The Fresh Connection and The Cool Connection, business simulation games about supply chain management.

Sources

- Webinar H. van der Drift

https://inchainge.com/resources/webinars/sop-competency-development-the-power-of-simulation/ - Research column by Dr. Lapide: SALES AND OPERATIONS PLANNING PART I: THE PROCESS

https://ctl.mit.edu/sites/default/files/library/public/article_jbf_soplanningi_lapide.pdf - Projeto de implementação do processo Sales and Operations Planning (S&OP) - caso de estudo by DANIELA ALEXANDRA DE SOUSA LIMA

- Stratx case study Demand forecasting

https://www.statworx.com/en/case-studies/demand-forecasting/ - Hubspot: A Comprehensive Overview of Sales and Operations Planning (S&OP)

https://blog.hubspot.com/sales/sales-operations-planning - The integrated S&OP and S&OE process

https://blog.flexis.com/the-integrated-sop-and-soe-process - Forbes

https://www.forbes.com/sites/forbesbostoncouncil/2019/08/20/five-ways-sales-and-operations-planning-enables-success-and-drives-business-integration/?sh=6b6fb64d3152 - Maine Pointe: Sales & Operations Planning: Why is S&OP Important?

https://www.mainepointe.com/insights-news/sales-and-operations-planning-why-is-sop-so-important#:~:text=Effective%20S%26OP%20provides%20stability%2C%20support,difficult%20to%20imitate%20competitive%20advantage - Supply chain movement: stepping-up the S&OP and IBP game!

- Tien standaard S&OP valkuilen

https://articles.involvation.com/nl/tien-standaard-sop-valkuilen

You might want to learn more about

Business games

A high-performing value chain needs the collaboration of team members from across the organization. Tearing down silos and creating the right cross-functional mindset, however, can be a serious challenge. So, what do you need in order to achieve success? Ideally, you’d like your team to experiment with different scenarios wherein they learn to overcome various obstacles.

Dive into our

knowledge base

Alignment

Blended learning

Experiential learning

Learning

Supply chain

Sustainability

- Sustainability

- Carbon footprint

- Circular Economy

- Does Green Governance drive the ride to a sustainable future?

- Everything You Need To Know About Eco-Efficiency

- Greenwashing: Everything you need to know

- Is it possible to measure the Triple Bottom Line?

- Sustainability v/s Circularity

- The 3Ps Series: People

- The 3Ps Series: Planet

- The 3Ps Series: Prosperity

- The Butterfly Diagram

- The Value Hill

- What are the 3Ps of Sustainability?

- What do we know about the Triple Bottom Line?