blogs

How can we measure circularity?

As more and more companies are increasingly making the transition towards a circular economy, there is a need to address the question: how do we measure circularity? Unlike a linear economy, where a product’s life span follows one straight line from manufacturing to consumption, in a circular economy the product can go through several life cycles.

Measuring circularity is a more complex process than measuring linear economy. In a take-make-dispose approach value is measured by a singular bottom line which is the financial aspect of the business. Whether, for example, the money spent in raw materials doubles when the product is sold to the consumer. In case of circularity, the loop after dispose closes. The raw materials are no longer disposed of but pushed back into the value chain to recreate, reuse, or recycle.

Due to this infinite-like loop, the issue of analytics in circular economy and what do we measure or how do we measure it is still a major concern. Circularity considers not only financial profit but several other variables such as product durability, usage intensity, recyclability, repairability, the number of users who are benefiting from the products, and so on.

In the course of their transition, several organizations and companies were quick to detect this issue and have made significant progress to measure circularity. What is even more interesting to discover is that, it seems, some of these measuring tools are quite industry specific.

Let’s take a closer look at them here below:

- Madaster Circularity Indicator (MAD)

- Circular Transition Indicators (CTI)

- Circulytics

- ‘CirculAbility’ Model

- ISO/TC 323

1. Madaster Circularity Indicator (MAD)

In her blog, ‘Madaster in Development’, architect Sander Bosman argues that “In the first place, it is a combination of measuring and assessing. Secondly, you need more than one tool to determine the variables.” The key to measure circularity, especially when we take into consideration the central aspect of ‘raw materials’, it becomes important to relook at the way we measure those raw materials. Madaster focuses precisely on the use of materials.

“It is about the circular use of materials from the past to the present, as well as from the present to the future.”

The Madaster Circularity Indicator strives to avoid the depletion of raw materials and to keep them in a loop of utility. It does so by allocating a certain value the reusing aspect.

Sander Bosman defines three circularity indexes which can be measured:

- The starting position: the degree to which reused and recycled materials are applied in the construction phase of a building.

- The length of the diameter (literally translated as ‘the largest possible distance between two points on a circle’): the expected lifetime of the materials in their current application; the longer a product can be used, the better.

- The circumference of the circle: determine the degree of ‘circularity’ of materials in the future, that is to say, the degree to which these materials could be reused and recycled.

2. Circular Transition Indicators (CTI)

Developed by the World Business Council for Sustainable Development (WBCSD), the CTI is a self-assessing tool for businesses to determine their circular performance across various dimensions such as business units, sites, and products. CTI focuses on both ‘circular’ and ‘linear’ mass flows within businesses to indicate a company’s ability to close material loops. It also allows businesses to:

- Identify circular opportunities and linear risks to improve longevity and resilience

- Set a baseline and monitor progress on the circular transition

- Respond to customer and investor inquiries

- Start value chain conversations on shared circular priorities

The Circular Transition Indicator follows a step-by-step process that flows in a loop. It encourages frequent assessments to monitor progress in the circular transition. Let’s take a quick look at the 7-step process of CTI below:

3. Circulytics

The Ellen Macarthur Foundation defines Circulytics as, “a tool to measure the circular economy performance of a company in a comprehensive way.” Circulytics ensures a company’s smooth transition into circular economy in 4 ways:

- Measuring the entire company’s circular performance and not limiting it to only products and raw materials

- Measuring current performance while setting up objectives that can deliver full scores

- Developing and supporting strategies that accelerate the transition to a circular economy, Each Circulytics scorecard is confidential and can only be shared with employees within the company.

- Engaging with stakeholders, such as consumers and investors to create a wholesome awareness about the need for circularity and take informed actions for it.

According to the Ellen Macarthur Foundation, a company’s Circulytics score card will feature the following:

- The company’s overall score and score breakdown by category and theme

- The score history

- A benchmark based on anonymized and aggregated results

4. ‘CirculAbility’ Model

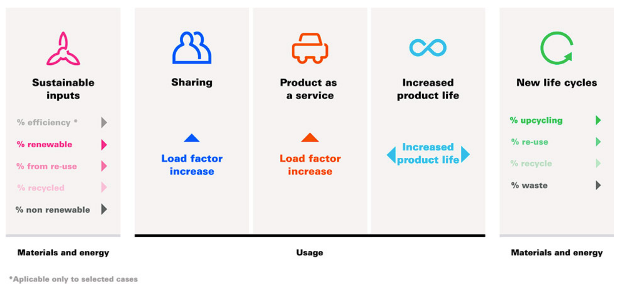

Circular economy can be evaluated in an efficient way once there is a measurement system in place, one where a set of parameters make it possible to quantify “circularity” of resources and how these resources contribute to the reduction of virgin material uses. What can act as an obstacle is that while the quantity of reusable materials can be easily measured, other features such as quality can prove to be less tangible. The CirculAbility Model, keeping this obstacle in mind, takes into account the five pillars of Circular Economy

The model defines a single circularity index, calculated starting from two components:

- flow circularity, which considers all the components of materials and energy in the phases of inputs (if renewable, from recycling, from reuse, etc.) and output (for recycling, reuse, landfill).

- circularity of use, which considers the use factor of materials, both by extending the useful life and by taking into account the application of the principles of sharing and “product as a service”.

5. ISO/TC 323

While the above four methods of measurement focus on either industries or a few components (mostly specific to raw materials) in a circular economy, there is a gap in a united global vision of how companies can come together to close the circle. The International Organization for Standards (ISO) tried to bridge this gap in 2018 by creating a technical committee that is solely dedicated to circular economy.

The Technical Committee, known as ISO/TC 323, works on “Standardization in the field of Circular Economy to develop frameworks, guidance, supporting tools and requirements for the implementation of activities of all involved organizations, to maximize the contribution to Sustainable Development.”

It aims to cover many individual aspects like production, distribution, consumption, along with wider issues such as behavioral and other impactful changes in the society.

Measuring circularity at a time when businesses are consciously trying to make the transition towards a more circular economy, becomes significant. It helps companies make informed and learned decisions on products, manufacturing, recycling, and various other aspects that can contribute to closing the loop on circularity. There are several tools available, it is only up to the company to decide what they prioritize when it comes to making the journey towards circularity.

Want to know more?

Our business simulation game The Blue Connection focuses on Circular Economy. It’s increasingly clear that modern businesses need to transform how they operate. The circular economy provides new business opportunities, but it also comes with its challenges to go from linear to circular. What does this mean and which challenges will you encounter?

Participants get to run their own virtual company called The Blue Connection, a manufacturer of e-bikes. There is an increased demand for the company to transform how they operate. To take advantage of the new business opportunities provided by the circular economy, the e-bike manufacturer has hired a new management team to transform the company’s linear value chain into a circular one. Participants take up the role of management and will learn how to adopt a circular approach by transitioning away from a take-make-dispose linear production towards a circular business model.

Reference

- Madaster: https://madaster.com/madaster-circularity-indicator/

- Introduction to the Circular Transition Framework: https://www.wbcsd.org/Programs/Circular-Economy/Metrics-Measurement/Circular-transition-indicators

- Ellen Macarthur Foundation Circularity Transition Indicator: https://emf.thirdlight.com/link/5ysbxdo664ve-2z8pc0/@/preview/1

- Enel CirculAbility Model: https://corporate.enel.it/it/economia-circolare-futuro-sostenibile/indicatori-performance

- ISO/TC 323: https://www.iso.org/committee/7203984.html