testimonials

Implementing S&OP in Large Corporations: Insights from Experts

"Including the business games into those workshops and supply chain academy sessions was really useful to bring the team together, get a feeling of community, and have fun. You learn a lot when you have fun, it’s an important driver of learning!"

Cyril Fougerouse

Cyril FougerouseSupply Chain Management Expert

Founder at Supply Chain Sensei

Envision a scenario where every segment of a large corporation's supply chain operates in perfect harmony. This isn't just an idealistic vision; it's the core promise of Sales and Operations Planning (S&OP), a process pivotal to modern supply chain management yet surprisingly underexploited.

S&OP is a process to align demand and supply planning across an organization. Despite its origins in the 1980s, the full potential of S&OP is still not realized in many businesses today.

In the dynamic world of global supply chains, the question arises: why is a robust strategy like S&OP still not fully leveraged by large corporations?

Effectively implementing S&OP presents challenges, from ensuring data accuracy to fostering cross-departmental collaboration. Businesses must navigate common hurdles like avoiding overcomplex process designs and recognizing S&OP's broader role beyond just supply chain functions. These challenges underscore the need for a tailored approach to S&OP that addresses each organization's unique requirements.

Cyril Fougerouse, independent consultant and CEO at Supply Chain Sensei, explains. “Introducing a standard best-in-class S&OP model across multiple business units can be complex”.

“Senior leadership engagement is a critical element and it’s sometimes difficult when leaders ‘do not know what they do not know’. It’s important to spend time on educating leaders on the goals you are trying to achieve and what they must get out of it.”

- Cyril Fougerouse

Tracy Cheetham (Director of Americas Education at Inchainge) agrees, emphasizing the following:

“Educating leaders on the objectives and the indispensable gains from S&OP is crucial. It's not just about adopting a system; it's about transforming the very fabric of how supply chains are managed.”

- Tracy Cheetham

Cyril and Tracy, each with their distinct expertise, have independently guided numerous companies through transformative S&OP implementations. Their innovative training approaches have been instrumental in the success of these initiatives.

“There is a stickiness with experiential learning. It stays with people,” Tracy observes, emphasizing the enduring impact of practical, hands-on learning experiences.

With their deep expertise and frontline experiences, Cyril and Tracy guide us through the intricacies of S&OP implementation in large corporations, shedding light on how this age-old process can be a game-changer in today's dynamic business environment.

Common Challenges in S&OP Implementation

Through their careers, Cyril and Tracy identified key challenges companies often face in S&OP implementation:

- An Uneven Playing Field: Deploying standard S&OP or Integrated Business Planning (IBP), an extended form of S&OP that integrates financial planning, across diverse business units of varying maturity levels.

[IBP is an extended form of S&OP that integrates financial planning with operations.] - Building Critical Mass: Enhancing the understanding of a critical mass of stakeholders and individuals directly involved in the process.

- Educating Leadership: Educating business leaders and senior executives on industry best practices and their roles as leaders in IBP.

Lessons from a FTSE 100 Company's S&OP Implementation

A Model for Success in Complex Environments

At a leading blue-chip company a unique training model was developed, leveraging the expertise of PMI and FAPICS, to facilitate supply chain transformations. This model baptized the SC Excellence Academy, had two main goals:

- enhance the understanding of those running the process and the leadership,

- implementing robust standardized S&OP or IBP models across diverse business units with varying maturity levels, while addressing each unit's specific challenges.

In over a decade, this training model was rolled out across 50+ sites, in different industries taking over 400 employees through the training program illustrating its widespread success.

Developing an Effective Supply Chain Academy for S&OP

Laying the Foundation for Successful Implementation

To begin their S&OP journey, companies can establish an internal Supply Chain Academy to support ongoing training for different seniority levels:

- Leadership Training: A concentrated program to give leaders a clear vision of the training goals and their role in the S&OP process.

- Empowering Key Decision Makers: Ensuring those in charge of the process understand both the theoretical principles and their practical application.

This academy serves as the foundation for recurring training, involving cohorts from different divisions and seniority levels, encompassing leadership and key decision-makers.

In our best practice of the SC Excellence Academy, the Leadership Training is an intensive, boot camp-like program, lasting 2.5 to 3 days. It provides a comprehensive overview of the curriculum and underscores the importance of leadership support during the implementation phase.

The Three-Phase Learning Journey

Designing and Applying the Training Model

Once the academy is set, it is time to design the learning journey and its practical application through a three-phase process.

Phase 1: Training design

The training design starts with a maturity assessment and mapping of theoretical knowledge within the company and the industry (e.g. APICS and ASCM body of knowledge). The design phase is crucial to tailor the program to learners' needs, identifying the company's specific challenges and target audience.

Phase 2: the Learning Phase

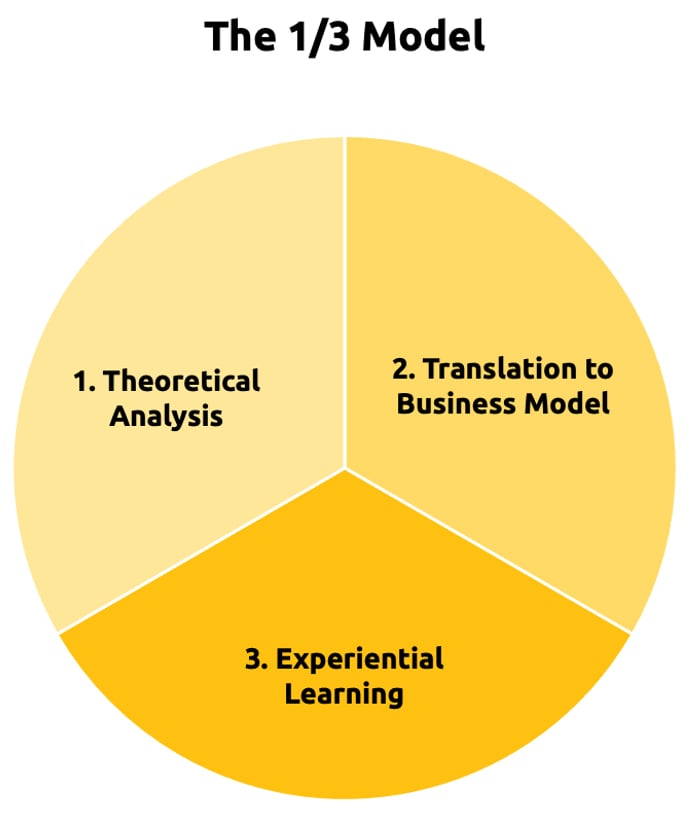

This innovative training approach divides time into three segments using the ‘one third model’.

Time division within the ‘one-third model’:

- Theoretical Analysis: Spending a third of the training on industry best practices and theoretical knowledge, brought in by experts like Tracy and Cyril.

- Translation to Business Model: Another third is devoted to adapting the theory to the company’s business model, with the aid of an internal 'partner in crime' to ensure relevance.

- Experiential Learning: The final third involves applying learnings through a business simulation game, like The Fresh Connection, to apply concepts in a risk-free, competitive, and fun environment.

This model allows for a deep and practical understanding of S&OP, encouraging decision-making and strategic thinking through simulation.

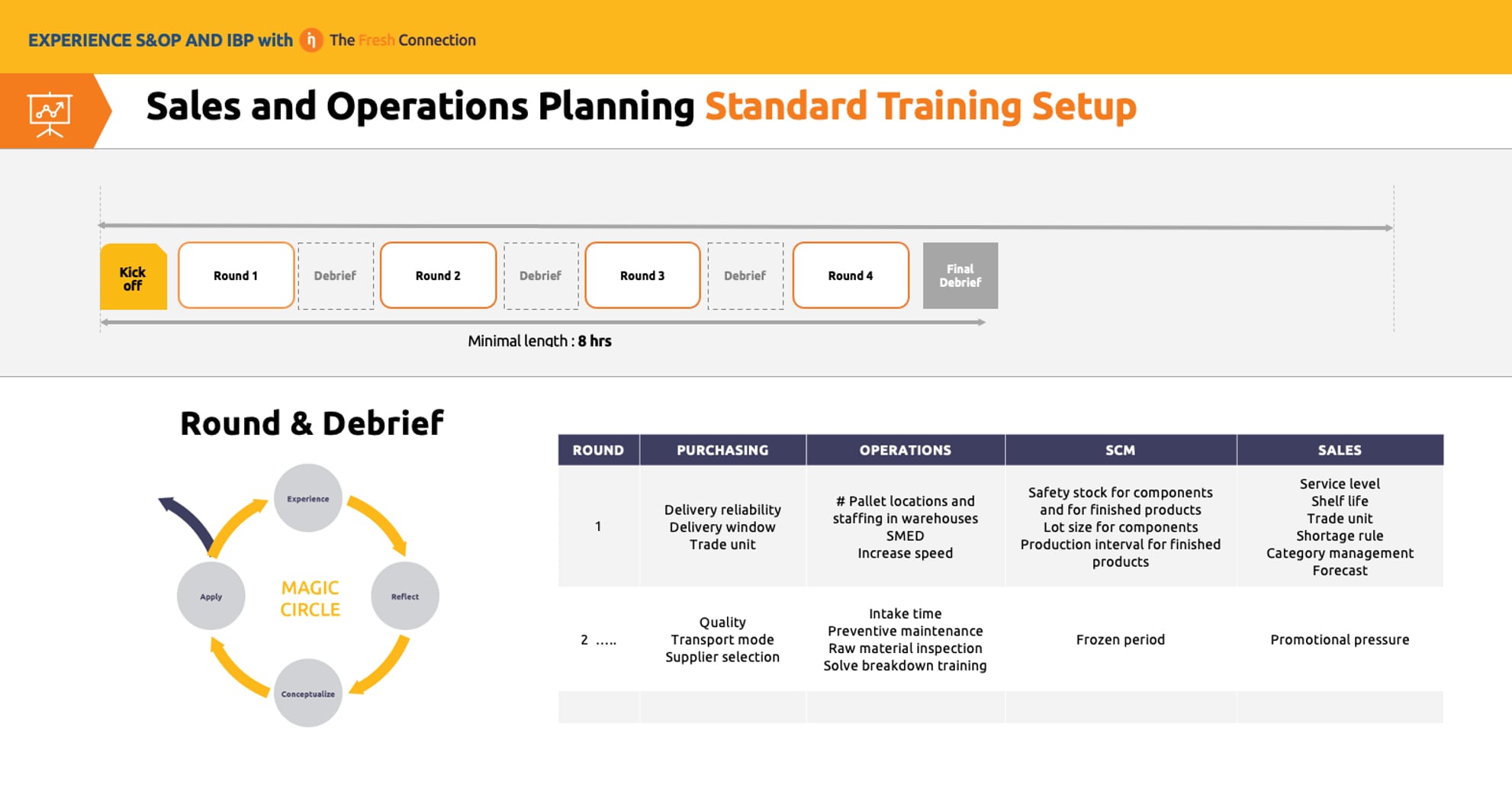

A key tool used in this phase is a business simulation game, such as The Fresh Connection. In The Fresh Connection (TFC) participants form teams of four members each and together they manage a virtual manufacturing company. It provides a sandbox environment that can simulate life-like challenges, enhancing participants’ decision-making and risk-taking without real-life consequences. Learners can gain hands-on experience in S&OP concepts, fostering teamwork and practical application in a risk-free environment.

“Including the business games into those workshops and supply chain academy sessions was really useful to bring the team together, get a feeling of community, and have fun. You learn a lot when you have fun, it’s an important driver of learning!”

- Cyril Fougerouse

While TFC is known for its detailed portrayal of supply chain dynamics, it is one of several tools that facilitate a deeper understanding of S&OP concepts and the 5-step S&OP cycle. The focus on teamwork, strategic decision-making, and the practical application of theory exemplifies the effectiveness of experiential learning in S&OP training.

Phase 3: Implementation

Upon completion of the training phase, the implementation phase, supported by consultants and coaches, allows teams to translate their learning into practical application. The leadership will also effectively support implementation because it was trained as part of the program.

Benefits of the One-Third Model

The Impact highlighted by former participants.

“For the S&OP process, the one-third model is a tried and tested methodology that delivers really good results”

- Tracy Cheetham.

Participants of this unique training model have highlighted several key benefits:

- Learning by doing: Practical Learning is central to S&OP training. The business simulation game allows employees to apply new principles in a risk-free environment, encouraging experimentation without real-world consequences. This approach prepares them to handle real job scenarios more confidently, where applying these concepts carries greater stakes.

- Breakdown silos: This experiential training approach fosters cross-functional collaboration, breaking down silos within the organization. It encourages participants to step into their colleagues’ shoes, understand their daily challenges, and see the perspectives of different departments.

- Team collaboration: This team-based learning experience encourages collaboration and highlights the importance of teamwork and the power of alignment.

- Engaging and Competitive Learning Environment: The inclusion of a business simulation game adds an element of fun and healthy competition, creating a more memorable and effective learning experience.

- Global Perspective: Conducting training sessions at various division headquarters allows for a rich exchange of best practices and perspectives, enhancing the overall learning experience.

- Accelerated Learning: By simulating real-world scenarios, this approach rapidly builds experience and insights that would typically take months or years to acquire during one's career.

“Learning by doing is not just a methodology; it's the essence of effective training.”

- Tracy Cheetham.

Why the One-Third Model Succeeds

Key Factors Driving Effective S&OP Training

The program's adaptability ensures it meets the unique needs of different business units. It encourages cross-functional collaboration and supports talent mobility, offering long-term learning opportunities and the ability to run recurring training programs. Both warm and cold feedback methods are used to measure the impact and ROI of the training. “Applying what's learned is crucial for any educational program's ROI,” Cyril emphasizes, underscoring the importance of practical application.

The success of the one-third model in S&OP implementation can be attributed to several factors:

- High Flexibility and Adaptability: Tailored to specific business cases, the program and simulation are highly adaptable, meeting diverse S&OP implementation needs across different units. This adaptability makes the program suitable for companies at varying stages of S&OP maturity, from novices to those enhancing existing S&OP processes.

- Cross-Functional Inclusion: Involving roles beyond the typical supply chain functions, like marketing, HR, and administrative roles helps all participants appreciate the broader impact of S&OP processes, see the bigger picture, and recognize their role.

- Talent management and Employee Mobility: The training boosts employee engagement and cross-functional knowledge, promoting versatility and adaptability in the workforce. It enables employees to transition smoothly across business units, unified by common processes and terminology.

- Progressive Learning: Beginning with supply chain fundamentals, the training program can progressively increase in complexity, enabling ongoing skill development in areas like end-to-end supply chain management, working capital management, and sustainability.

- Recurring Programs: The ability to rerun these programs ensures new employees can be brought up to speed effectively.

- Feedback Mechanisms: Collecting both immediate (warm) and long-term (cold) feedback helps measure the impact of training on job performance and overall business outcomes.

Conclusion: The Integral Role of Training in S&OP Success

A Proven Methodology for Enhancing Supply Chain Management

In conclusion, Tracy and Cyril's expertise highlights the critical importance of training in S&OP implementation. Their journey reveals a transformative process, where each training session is an expedition towards supply chain excellence.

Utilizing the one-third model, a well-established method in the industry, they provide a roadmap for large corporations seeking to upgrade their supply chain management capabilities, whether establishing new S&OP processes or refining existing ones.

By equipping involved individuals and leadership with the necessary knowledge and tools and providing a safe environment for practical application through business simulations, organizations can effectively transition to new or enhanced S&OP strategies.

“The true measure of any training program's success is its lasting impact on the way we work.”

- Cyril Fougerouse

Participants will go through an individual micro-learning experience to get acquainted with the S&OP fundamentals, team-play sessions within business simulation, such as The Fresh Connection, will follow – all without the need of a facilitator. This new training approach allows companies to easily scale up their training to thousands of learners overcomes scalability barriers, as well as increase participants engagement by accommodating the diverse learning needs and providing flexibility.

What’s next? Unleash S&OP training across the entire organization.

Traditional training formats in large manufacturing companies often face hurdles like time constraints, resource-intensive facilitation, limited flexibility to suit the learning preferences of diverse audiences, and more. These challenges often hinder the scalability of training programs across various business units.

When designing in-company trainings, scalability turns out to be one of the main challenges. Inchainge is gearing up for the future of L&D with its innovative self-guided training proposition. Bid farewell to traditional instructors; participants are now the architects of their professional journey. By blending individual micro-learning experiences and team-play in our established business simulation games, scaling your S&OP training across your entire company has never been easier.”

Hans Kremer

Hans Kremer

Co-founder and Director at Inchainge

View LinkedIn profile

As mentioned by Inchainge co-founder Hans Kremer, Inchainge is working to redefine the training landscape by designing a new proposition that blends micro-learning and hands-on experience in our business simulations. Through the individual micro-learning, participants will get familiar with S&OP fundamentals, and will get the chance to immediately apply the learnings through a team-play sessions within business simulations, such as The Fresh Connection – all without the need for a facilitator.

This new training approach enables companies to easily scale up their training to thousands of learners, overcoming scalability barriers and increasing participant engagement by accommodating diverse learning needs and providing flexibility.

Cyril Fougerouse

Cyril FougerouseSupply Chain Management Expert

Founder at Supply Chain Sensei

View LinkedIn profile

brings extensive experience in complex international organizations such as GKN, Valeo, Faurecia, and lately GE with wide operational background in industry including Production & Program Management, ERP Implementation, Lean, Supply Chain Management, Operational Excellence, Customers & Suppliers. He founded Supply Chain Sensei (link to LinkedIn page) in 2022 to help others be successful.

Tracy Cheetham

Tracy CheethamDirector Americas Education at Inchainge

View LinkedIn profile

has an extensive background in supply chain management, consulting, education, and corporate engagements. She had collaborated with a global network of supply chain experts and facilitators to customize and conduct experiential workshops in international organizations such as GKN, LVMH, Essilor, Albea, and the United Nations missions in Africa.

PMI Production Management Institute provide Operations and Supply Chain Management education, guided by three fundamental pillars: experienced practitioners as trainers, globally recognized certifications, and business games for experiential learning.

FAPICS, currently AfrSCM, promotes international best practices in supply chain management in companies and universities with innovative educational tools like business simulations (serious games).