event

Resilience Hands-On: Experience a Resilient Value Chain

Day 1: Thursday, October 13th 2022

Day 2: Thursday, November 3rd 2022

15:00 - 17:00, CEST (Central European Time, UTC+2)

Wherever you are... Online!

For more information, please visit our webpage for Circularity Hands-on: https://inchainge.com/inchainge-leadership-program/rho/

Experience the opportunities and challenges of a resilient value chain

“Are you still managing risk, or are you already resilient?”

At the latest with the introduction of COVID-19, many companies have realized that there are countless unexpected risks in their supply chains.

Dependent on low-cost margins of global supply chains, a complex multiple-tier supplier base, or intransparent networks, many companies have been fighting to keep up their performance, efficiency, and sustainability of logistics operations during the COVID-19 pandemic.

How can a company respond to unexpected events and recover from disruptions?

This is the key question we aim to tackle during the program of Resilience Hands-On, but not on paper, but by taking action.

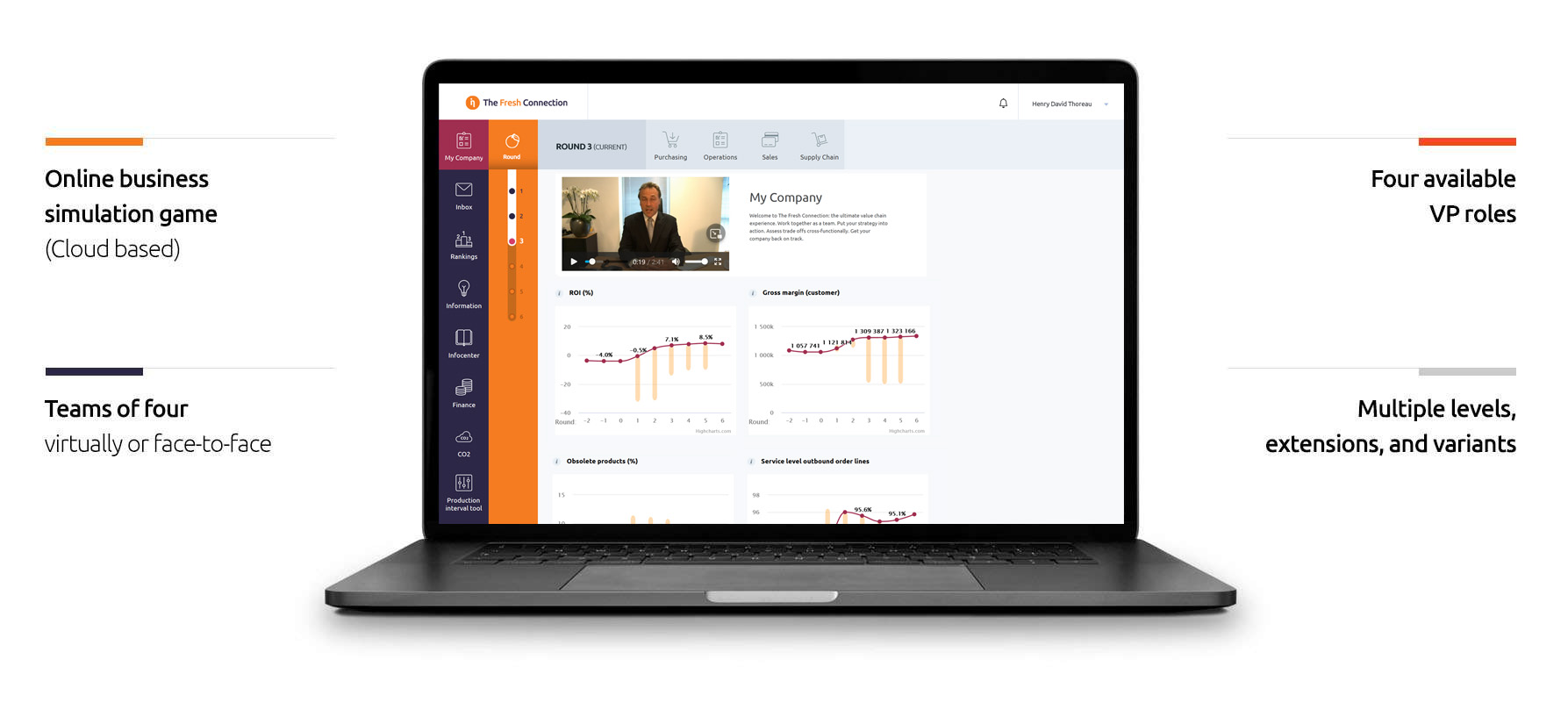

The 3 week-long program Resilience Hands-On aims to go from abstract ideas to real change and thereby substantially increase the speed to achieve resilient value chains.

At the core is the power of experience – you and three other team members will dive into an engaging and immersive learning experience where you must manage a virtual manufacturing company end-to-end and make sure it is resilient enough to deal with disruptions.

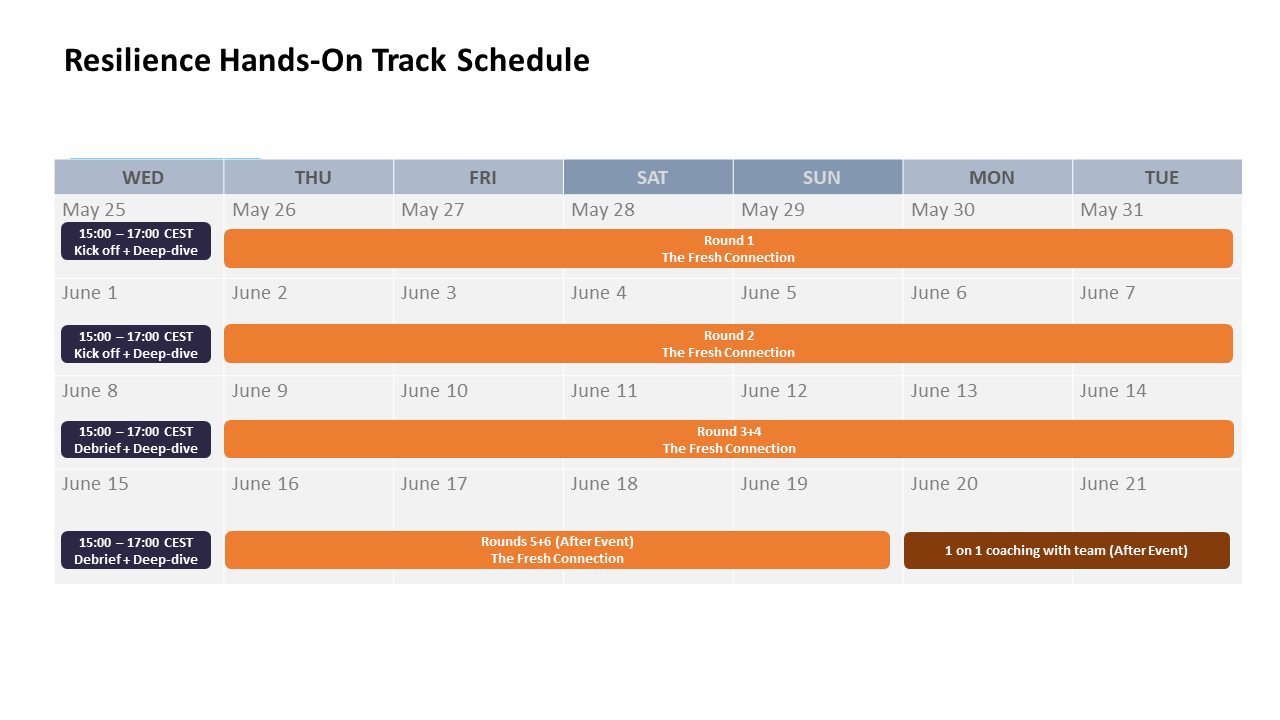

The program: Maximum flexibility to accommodate everyone’s schedule

Small-time investment: participants only invest 2 hours/week together with all other participants (in dark blue) and are flexible on how much and when they spend time on the decision-making with their team (in orange).

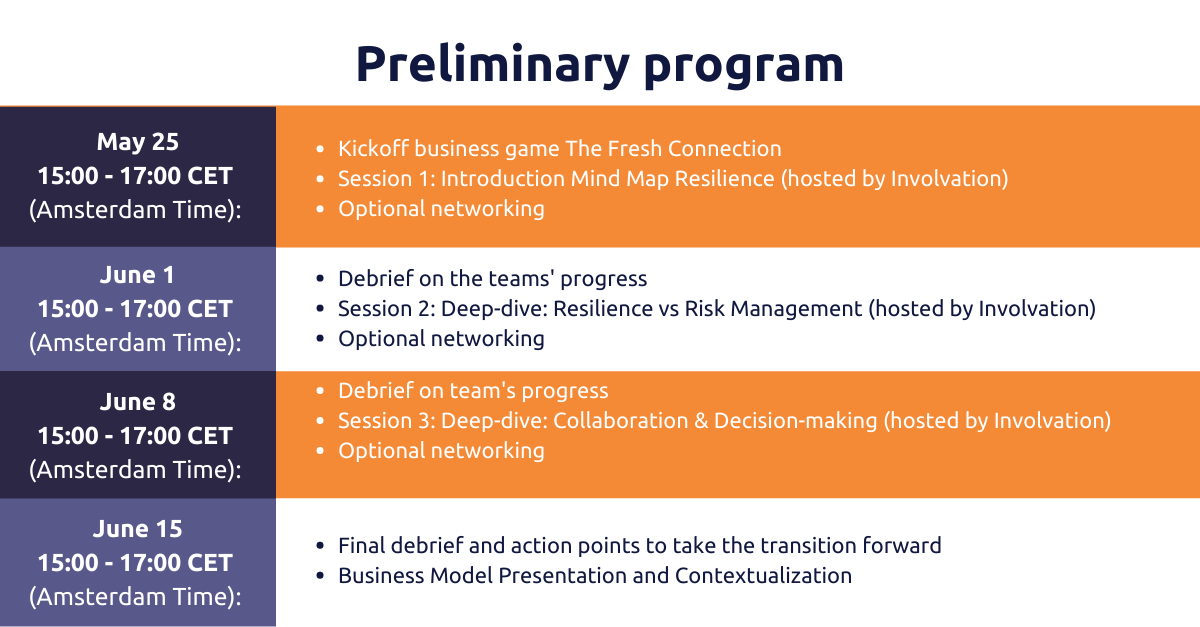

The online program includes the following elements

1. Decision making in the business simulation game

During 6 rounds of cross-functional decision-making in the online business game The Fresh Connection, teams must manage a manufacturing company. Teams do so in their own time and pace over the course of the week, to accommodate everyone’s schedule. Each round introduces new elements to consider: mapping out the value chain | making the business profitable | dealing with suppliers | optimizing operations | retailer contracts | dealing with disruptions| E2E strategy implementation & more.

2. Debriefs

Getting insights into how the decisions impacted the performance and resilience of the company. This is where mistakes are uncovered and analyzed, where good decisions are laid out and where the (experiential) learning happens!

3. Inspiring deep-dives & showcases

Our track partner Involvation will complement the program with inspiring deep-dive sessions where best practices, learnings from past experiences, and (un)successful showcases will be presented. Showcases of business models from the real world will complete the bigger picture of resilient business models and together with the experience that participants gained from the business game, The Fresh Connection, we will build the bridge between resilience in theory and in practice.

Deep-dive 1. Mind Map Resilience – May 25th

During this deep-dive, our partner Involvation will guide the participants through the Mind Map Resilience to provide them with a holistic view of supply chain resilience, addressing all the key elements (Supply Chain Design, Collaboration, Behaviour, Agility) to reach it.

Deep-dive 2. Resilience vs Risk Management – June 1st

After the first round of decision-making with The Fresh Connection, participants will have a first practical experience of the difficulties in managing a resilient value chain. But what are the main differences with the traditional risk management approach? During this deep-dive, our partner Involvation will make a focus on the key elements of the two approaches, highlighting the benefits of a “glass-half-full” perspective when designing a resilient supply chain.

Deep-dive 3. Collaboration & decision making – June 8th

One of the main aims of Resilience Hands-On is to help companies achieve a more resilient value chain. But which are the key elements in order to do it? In this third deep-dive, Involvation will focus on the importance of having a broad knowledge of the company’s supply chain (e.g. third and fourth-tier suppliers) as well as a strong internal and external collaboration to build a more resilient value chain.

Deep-dive 4. Business Model Presentation and Contextualisation – June 15th

For the last deep-dive, we will take over from our track partner to help the participants understand how the learnings can be contextualised and applied to their own companies’ day-to-day activities.

This will mean reviewing situations that could be encountered in the business simulation game as they can easily be repeated in professional context. The objective of this exercise is to build the bridge to the participants’ day-to-day work and to help them to recognise those circumstances and be ready to respond.

4. Applying the learnings to your context

After the 3-week program, we set up a coaching session with each team to go through the learnings and discuss how we can translate them to their day to day activities and create real change.

5. Get all the basics on Supply Chain Management

As a part of the program, you will receive a copy of the textbook Mastering the Supply Chain. Using the textbook is optional and is meant as a way to provide all participants with everything they need to have a foundation of knowledge on Supply Chain Management.

6. Innovative networking

We will also do some networking activities with the participants to build new connections and share best practices.

Pricing

Participate as an individual for €375

Participate as a team of 4 people for a total of €1400

7. Awards

Participants of Resilience Hands-On will receive a certificate of Participation. Winners will get a chance to compete in the Global Pro Challenge Finals.

Our Track Partner:

![]()

Involvation is a consultancy and implementation firm that is focused on improving the supply chain and its management. They help all manner of organisations, large and small, to take the decisive step: the step from the challenge to a sustainable result. They do so by drawing inspiration from the possibilities they see, by looking just that little bit further.

.